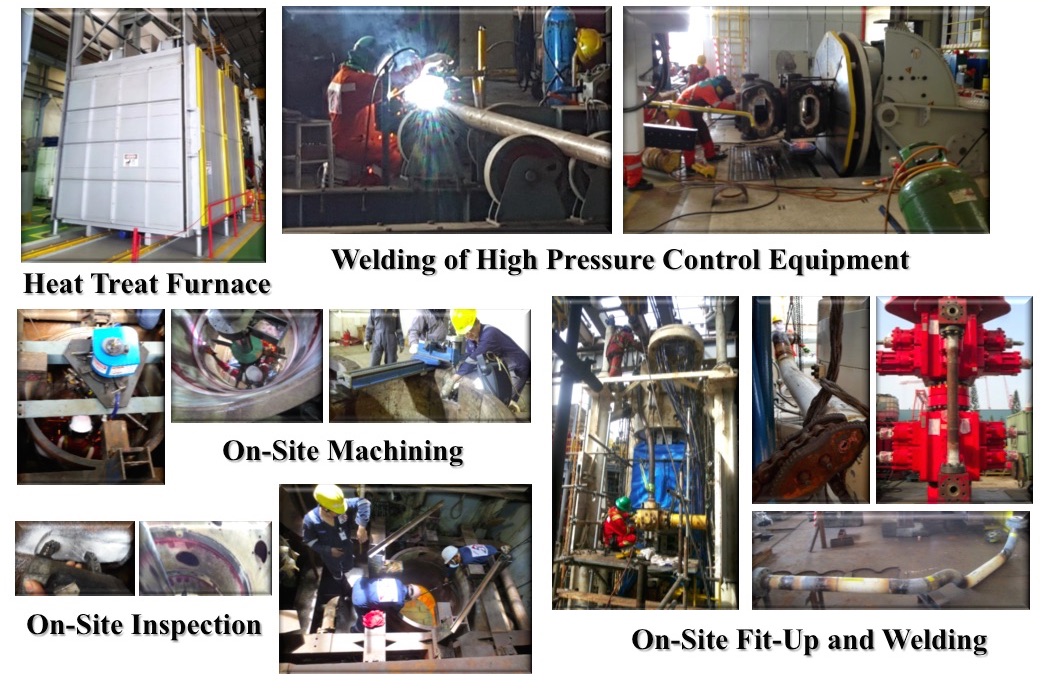

Four CNC SubArc Welding

Automatic Welding

Semi-automatic Welding FCAW & MIG

Manual Welding TIG & SMAW

Cladding Inconel 625, SS 316L Aluminum Bronze

Machining

Two CNC 5-face Double Column Milling & Boring

One CNC Horizontal & Vertical Milling

One CNC Horizontal Boring

One CNC Vertical Lathe Turning

Four CNC horizontal lathe turning

Three manual horizontal lathe turning

Two CNC machine center

Inspection

Dimensional

Positive Material Identification

Hardness Testing

Ultrasonic Testing

Magnetic Particle

Dye Penetrant

Heat Treatment Furnace

High Pressure Waterjet Blasting

Hydraulic, Electrical, Pneumatic Test Units

High Pressure Test Facilities

13-5/8" 10K Double Ram BOP, Cameron Type U

13-5/8" 10K Single Ram BOP, Cameron Type U

13-5/8" 5K GK Annular BOP, Hydril

13-5/8" 5K Double Ram BOP, Hydril

13-5/8" 5K GX Annular BOP, Hydril

Please email to sales@rmes.com.sg for further enquiries.

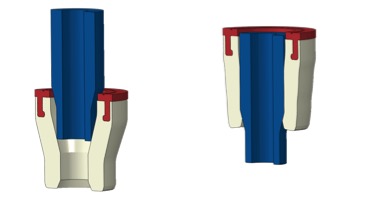

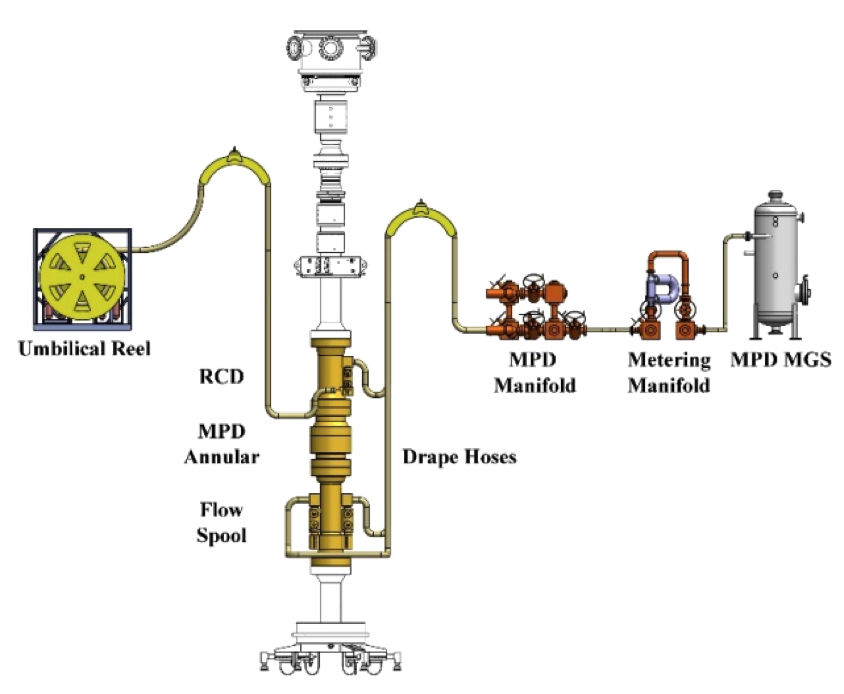

The RMES MPD/RCD is designed to be a flexible system that can be constructed to suit the customers’ requirements.

“THE ADAPTIVE SYSTEM” Available basic configurations are:

The RMES MPD system is designed to be flexible and can be constructed to the requirements of the Oil Company, the Drilling Contractor and the rig or vessels limitations.

RMES MPD Joint

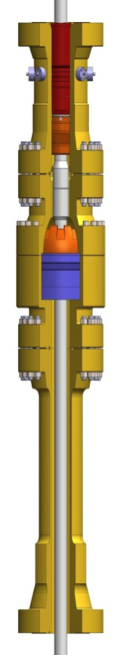

RMES Rotating Control Device

RMES MPD Annular

RMES Flow Spool

Advanced Element Simulation.